Optimation’s performance analysis

By comparing with Optimation’s reference material, we can quickly get an idea of expected performance. Based on this material, we identify the areas that can lead to the most effective improvements with regard to emissions, availability and production capacity.

Optimation has solid experience of processes in both the combined heat and power industry and the paper and pulp industry.

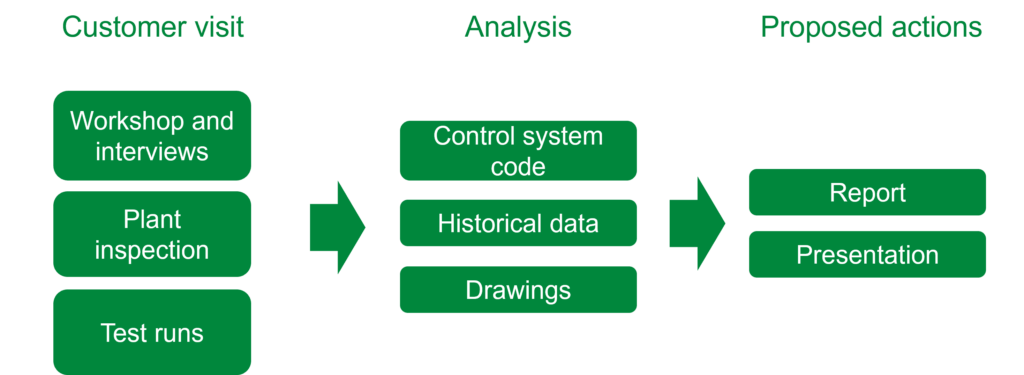

The analysis includes:

- Customer visit with associated plant inspection. If necessary, smaller test runs can be done in consultation with the customer.

- Analysis of drawing documents, flow charts, control system code and trend data.

- Workshop / interviews with the managers and operators.

Deliveries

Report containing proposed measures and assessed potential for improvement based on current performance in the sections below that are relevant depending on the type of boiler:

- Fuel management

- Stoichiometry and emissions

- Steam dome level

- Turbine / electricity production

- Overheating control

- Bed temperature

- District heating production

- Observations from general review

Schedule

The performance analysis is normally performed during 3-4 weeks.

For more information, please contact Olle Nilsson below: