Improved efficiency at Boliden in Ireland

The 3DPM system from Optimation Advanced Measurements, former MBV Systems provided Boliden Tara mines in Ireland with the potential to improve communication between the mine and the grinding mill. “When we learn to use this to its full potential, it will provide the opportunity to optimize production at less cost”, said mill manager George Wilkinson already in 2012.

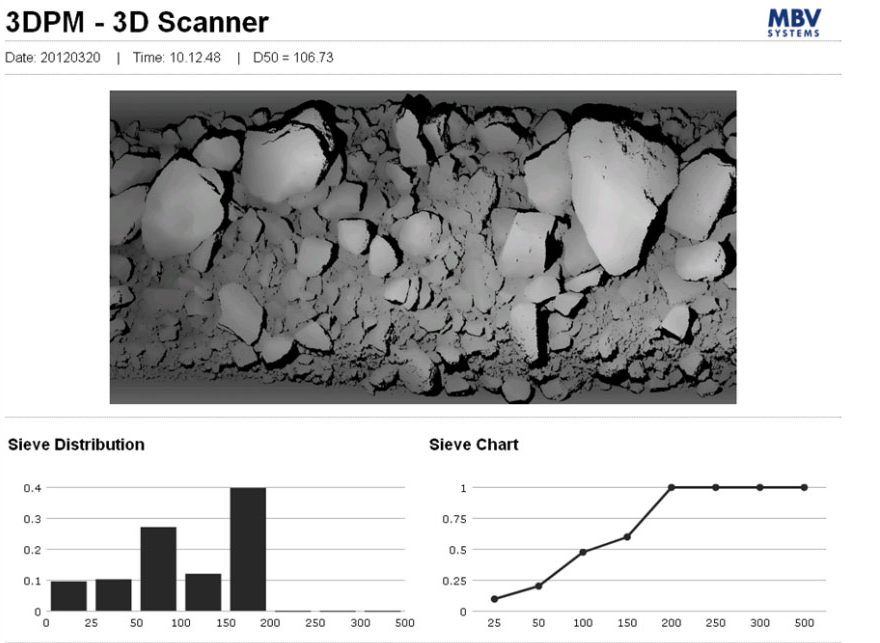

Particle measurement on conveyor to grinding mill

Boliden Tara mines Limited in Knockumber, north of Dublin, Ireland, installed the 3DPM system early 2012. The 3DPM system is installed to measure the particle size on one of two conveyor belts transporting material from the coarse ore storage into the recently installed autogenous grinding mill. In this mill the ore is ground into the finer particles as the first step in the process resulting in zinc and lead concentrate.

Very useful feedback to our supplier

The information from the 3DPM system has provided the mill management with insight into the effects that feed particle size has on the mill throughput. “The information about how particle size affects mill efficiency is very useful as feedback to our supplier, our colleagues in the mine”, says George Wilkinson.

Optimize mill throughput and lower production costs.

The information from the 3DPM system was valuable input into an ongoing fragmentation project at Boliden Tara Mines, with the purpose to optimize mine and mill process and improve integration. “This project, with input of the new information about optimal particle size, has the potential to optimize blasting in the mine. This in turn could optimize mill throughput and lower the production cost”, sayd George Wilkinson, mill manager at Boliden Tara mines already back in 2012.

The story did not end back in 2012

The 3DPM system is still operational even today and brings valuable information to Boliden Tara, with only wear parts exchanges during the years of operation. Since 3DPM does not demand recalibrations the data from 2012 can be compared with today’s data, which is a strength when it comes to optimization and possibility to back track any interesting happenings in the particle size data.

Planning for the future

Boliden Tara now plans to start using the optional anomaly detections first tested at Boliden Garpenberg.