Custom Solutions

Theoretically we can do machine vision custom solutions for any task and we have always said – “if you can see it, we can measure it”. But we have also learnt that to be able to do good reliable data extraction 24-7, we need to know the process. In practice it means that we focus on industrial measurement tasks in harsh conditions since that involves processes we are familiar with, or can relate to, from our years of experience. We are used to be involved in optimization projects where the goal is to increase production, quality, or lower environment impact.

Within our domestic industry we have been hired for very different customer cases like:

- Woodworking joints, glue inspection

- Metal works, pipe dimensioning

- Mining industry, drill motion tracking

- Car industry objects inspection

- Green iron ore pellets quality control

- Cheese manufacturing

- Bread manufacturing

- etc

Through our expertise we are also sometimes hired for more unexpected missions, like when the Royal Library of Sweden asked if we could digitalise their massive record collection through an innovation contest. We ended up being one of three companies who was sponsored to build a vision-based music digitizer prototype.

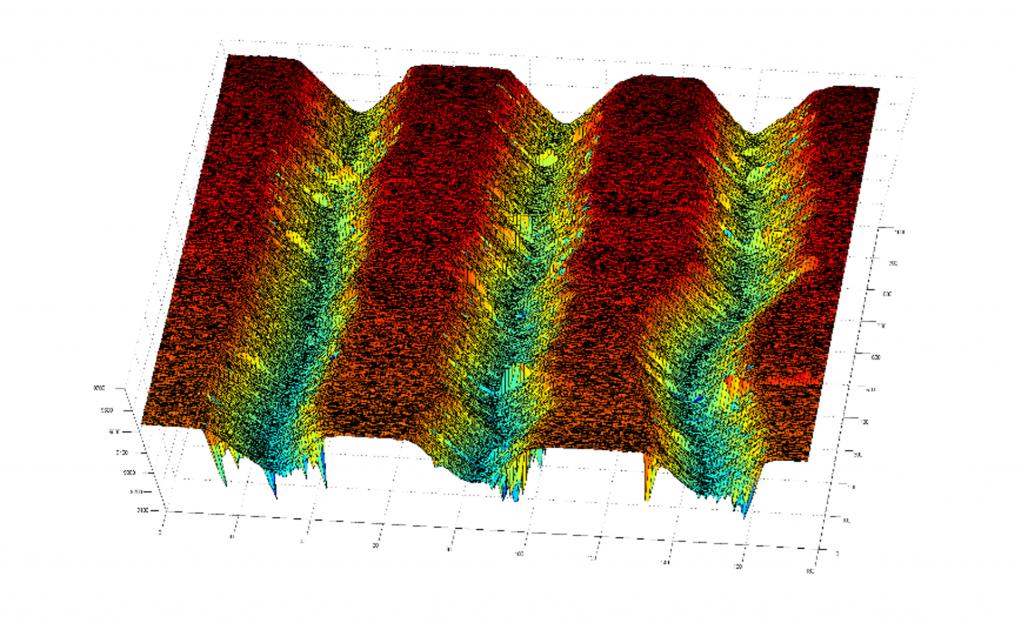

We used the same basic principle as in our products 3DPM and 3DSI, camera laser triangulation, but in this case we measured in the micrometre scale instead of millimetres.

In the end the music listening quality was too low, but as a proof of concept the project was a success, and now we just have to learn about music filtering and wait until the hardware development makes us reach “the perfect sound”.