Operational Decision Support

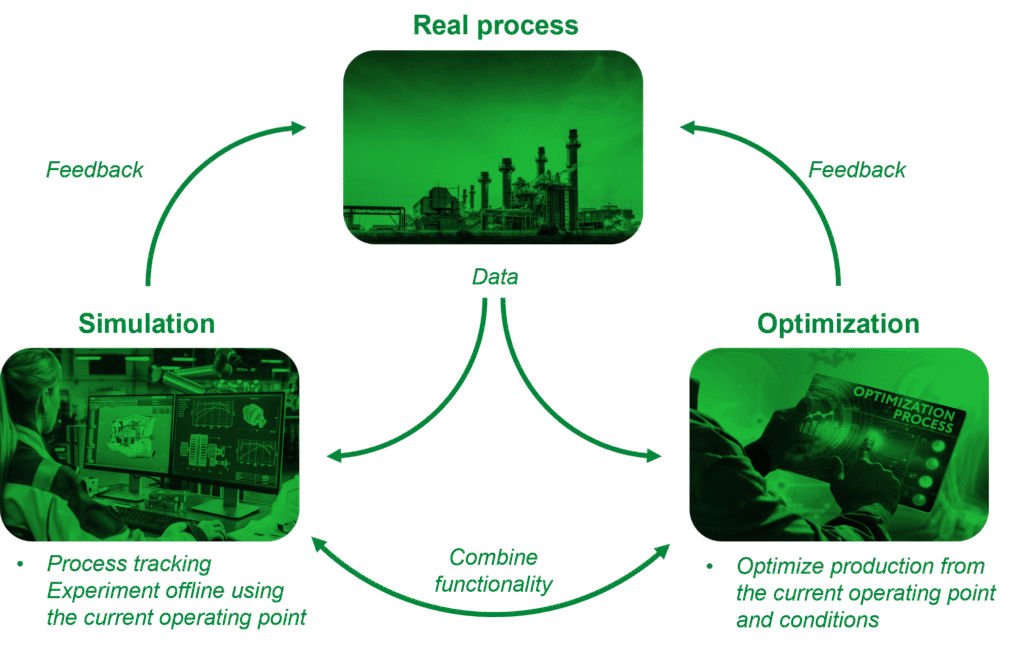

In a production facility, different production objectives may conflict with one another, making it challenging to evaluate the process as a whole. As conditions related to sustainability and energy production change, new issues and challenges emerge for both existing and new facilities. Model-based decision support is a powerful tool that can help manage daily operations more efficiently. By combining data from a production unit with a higher-level process model, it is possible to both simulate and optimize various scenarios based on the current operating conditions.

With a fast and reliable simulator, it is possible to perform so-called ”What if…?” simulations. By monitoring the process in real time and saving a specific operating point offline, different strategies and production plans can be evaluated in a computer-based environment. The best outcome can then be applied in the actual plant, and new simulations can be run as needed. The tool can be used for both maintenance planning and to gain a deeper understanding of the process. We believe there is a great value in the industry in being able to collect, analyze, and share results among different users.

However, it is often difficult – if not time-consuming – to define and evaluate all possible strategies and outcomes. Instead, by formulating the process as an optimization problem, it becomes possible to calculate an optimal production plan based on the current conditions. This approach allows for applying both ”hard” constraints on the process, such as maintaining buffer tank levels, and defining ”soft” objectives related to energy consumption and sustainability. Optimization can serve as a valuable complement to simulation, or be implemented as a higher-level, automated control of the entire process.

Why?

Reduce production losses

- Simulate the process to determine the most suitable time for planning maintenance and shutdowns.

- Fully utilize system margins and avoid unnecessary ramp-downs by applying optimization.

Optimize from a high-level perspective

- Formulating the process as an optimization problem makes it possible to balance competing operational goals, helping to avoid sub-optimization of individual process sections or isolated production objectives.

Flexibility and continuity

- An accessible decision support system gives more people the opportunity to make informed decisions, reducing dependency on key personnel and minimizing risks during staff absences.

Increased process understanding

- Operator training using simulation and optimization helps build a deeper understanding of how different parts of the system are interconnected. We believe this strengthens employee engagement and improves communication – both internally and externally.

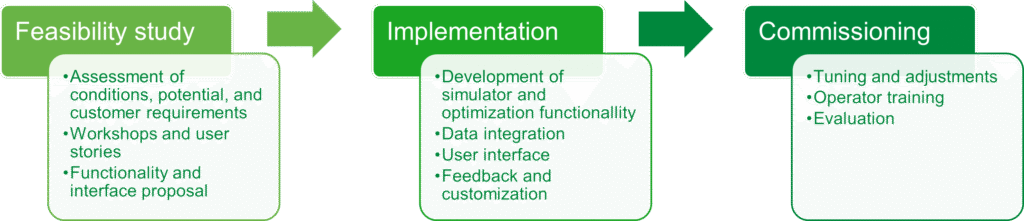

How is it done?

Areas of use:

Our operational decision support system is not tied to a specific industry or process, but is developed in close collaboration with our customers. Example applications include:

- Power generation facilities: Reduce imbalance costs with a decision support tool that helps align the dispatch plan, and ensures it is followed.

- Pulp and paper mills: Develop production plans for various product types, taking into account delivery deadlines, raw material and fuel costs, and capacity limitations.

- Mining industry: Optimize production rates and plan maintenance strategically.

Contact us to learn more about how a decision support system can benefit your facility.