Process Water Management

By simulating process water management it is possible to optimize the current plant as well as future investments to fulfill the current and future requirements as cost-effectively as possible.

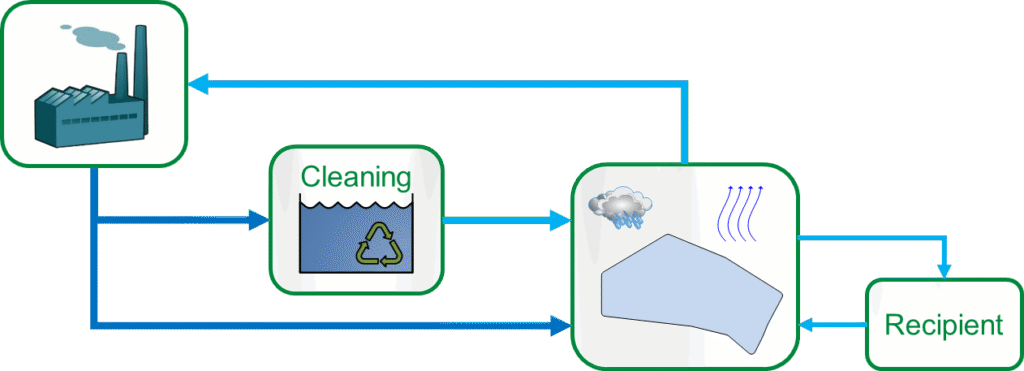

Sustainable water usage in a production facility

The need for resilience, sustainability and resource optimization becomes certainly higher within the process industry. This also means an increased need on water management in production facilities. It can be for example how much water is used, when it is used, what contaminants are in the water and how they are released in the environment. There are as many questions around water management as there are production plants that use water. We at Optimation can help you answer these questions with our simulators for decision support!

By connecting dynamic models for production and their water dependence with eventual reservoirs the plant’s water system can be simulated annually. Then it is also possible to add the yearly environmental variations (for example increased inflows, precipitations, evaporation, etc.) to analyze the whole plant’s effect on the water in the local environment.

Why simulate?

Evaluate and optimize the compliance with environmental requirements

- Simulate the process to evaluate how the current environmental requirements are fulfilled throughout different periods of the year.

- Evaluate how the current water management can be optimized and continues to comply with the environmental requirements .

Analyze unusual events

- It can be hard to know how a plant reacts to events that do not happen very often.

- For this the simulation is a powerful tool that can be configurated to expose the plant to unusual events of which the consequences would otherwise be hard to analyze.

- For example, how a hundred-year-rainfall (rainfall that only happens every hundred years) affects the level in the reservoirs.

Optimize investments

- Simulations before an investment in the plant enables the requirements to be fulfilled as cost-effectively as possible.

- Different scenarios and plant layout can be simulated in order to optimize the future plant.

Increase process knowledge

- Simulating an increase the knowledge for the process and its mechanisms, which leads to taking better decisions.

Our decision support is not connected to a specific industry or process, it develops in consultation with you as client, from your specific needs.

Contact us to learn more and know about what opportunities there are to simulate your plant.