PSD measurement and anomaly detection

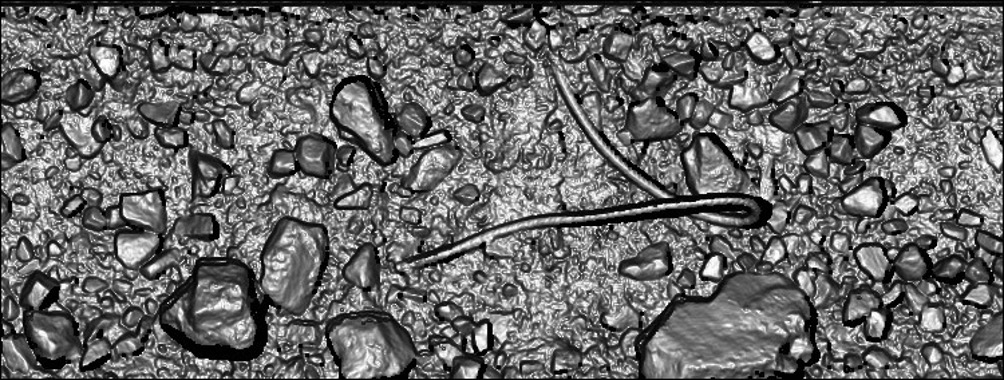

Boliden Garpenberg needed increased control of boulders and rock bolts after crushing. With 3DPM® they can now reliably detect these anomalies before they cause belt tear, destruction, and un-scheduled stops further down the production line. Moreover, they can also measure online particle size distribution (PSD). As a result, they can perform long term production optimization.

3DPM at Boliden Garpenberg, Sweden

Boliden Garpenberg, one of the most modern mines in the world, wanted to identify boulders and rock bolts on-line after crushing. We already had a robust product for 24-7 particle size distribution measurement. Therefore, we offered 3DPM with two new options. We simply added intelligent algorithms for boulder and rock bolt detection. These were new features in 3DPM, but we guaranteed the functionality. Boliden did the approval themselves, and now they have multiple systems installed at different sites.

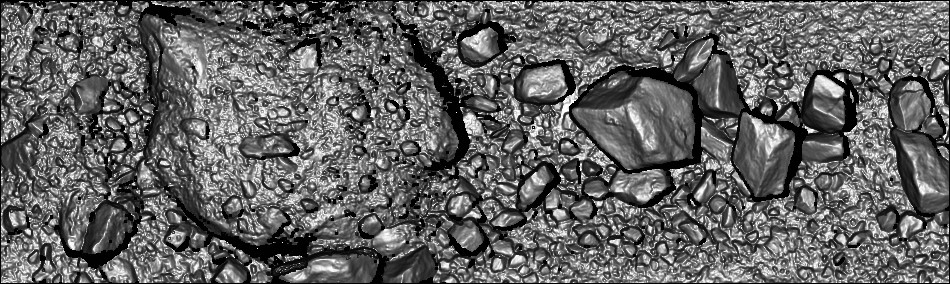

Rendered representation from 3D data showing a detected boulder

The solution is based on high resolution 3D laser triangulation hardware. By using 3D technology our algorithms can perform well independent on disturbances, like moisture or colour variations.

Boliden is very satisfied with the results

Andreas Forslund, project leader at Boliden Garpenberg, says:

They [Optimation] have delivered equipment that provides us with reliable boulder and rock bolt detection in a demanding environment. The equipment has given us the opportunity to take control of where we handle boulders and rock bolts in our feeding line. This also means that the stops generated can be handled in a safer and easier way.