Boliden has decided to install another 3DPM system

World-class metals company has selected to install another 3DPM particle size distribution measurement system from us.

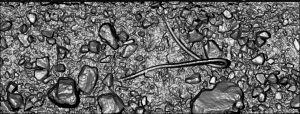

We are very proud that Boliden has decided to install another 3DPM system in their mine in Garpenberg. Our first system we delivered four years ago when Boliden was searching for a system which could help them to improve their process knowledge and control strategies for crushers and grinding mills at Aitik. Three years ago they wanted to push the limit even further at their Garpenberg facility to be able to detect boulders and rock bolts on-line in a safe way. These were new features in 3DPM but we guaranteed the functionality. Now three years later the system is operational at Boliden Garpenberg, and an additional system is commissioned at Boliden Aitik. When this new order is delivered this spring, Boliden Garpenberg will then have two similar system in operation in their mine. With all these systems Boliden can take control of particle size, volume flow and now also safely detect unexpected boulders or rock-bolts after their crushers.

Within mining and metal industry, crushers and grinding processes are big energy consumers, improved handling within these areas are therefore necessary for a long term sustainable production.

Boliden is very satisfied with the results. Andreas Forslund project leader at Boliden Garpenberg says:

They have delivered equipment that provides us with reliable boulder and rock bolt detection in a demanding environment. The equipment has given us the opportunity to take control of where we handle boulders and rock bolts in our feeding line. This also means that the stops generated can be handled in a safer and easier way.